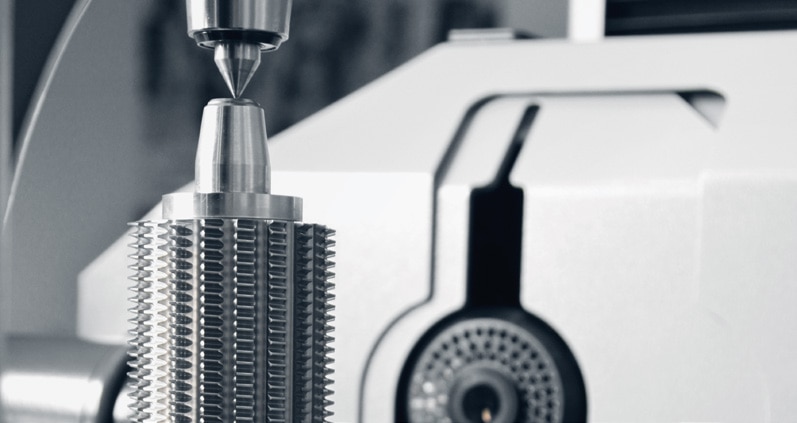

The universal measuring machine for fully-automatic inspection of cylindrical hob cutters.

hobCheck

The ZOLLER hobCheck, is the universal measuring machine designed for fully-automatic measurement and inspection tasks of cylindrical hob cutters.

hobCheck

Overview

The ZOLLER hobCheck opens up new possibilities for comprehensive, economical and fully automatic measurement and inspection tasks. With an intelligent combination of transmitted light image processing technology and sensors, more than 15 parameters, such as tooth profile, concentricity, wobble, pitch and shape tolerance, are assessed precisely in seconds.

User-friendly software and an intuitive graphical user interface allow for the simple creation of measurement procedures, from random sampling to complete measurement tasks. In addition, hobCheck offers a comfortable, convenient wear and tear evaluation on the tooth head for regrinding.

Efficient

Tooth for tooth: fully automatic, comprehensive measurement of hard metal or HSS milling cutter parameters in accordance with DIN 3968

Distortion-free

CNC-controlled, swivelling optic carrier for distortion-free measuring of the tooth form

Fully automatic

Intelligent combination of image processing technology, CNC axes, and measuring sensors

Robust

Seamless documentation of extensive measurements according to DIN 3968

User-friendly

Software with an intuitive graphical user interface for easy creation of measuring procedures

Comprehensive

Opens up new possibilities for fully automatic, efficient, and complete measurement of milling cutters

Convenient

Offers wear and tear evaluation on the tooth head for regrinding

Book your

in-person demo

Book a free demo for the hobCheck at our Advanced Innovation Centre where you can see the full scope of ZOLLER technology and how it can transform the way you work.

Download the full specifications

Get the full technical data on the hobCheck today. Discover the key data points including information on measuring range, accuracy and a full list of features.