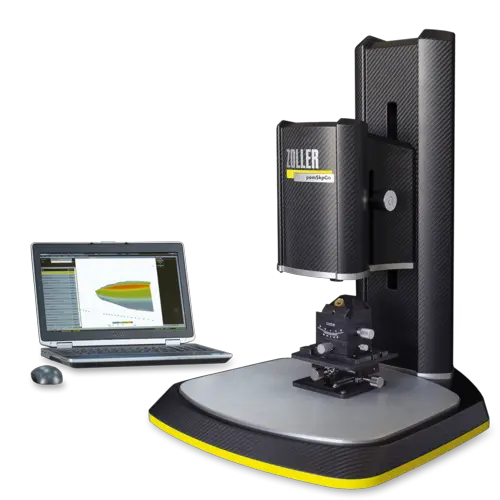

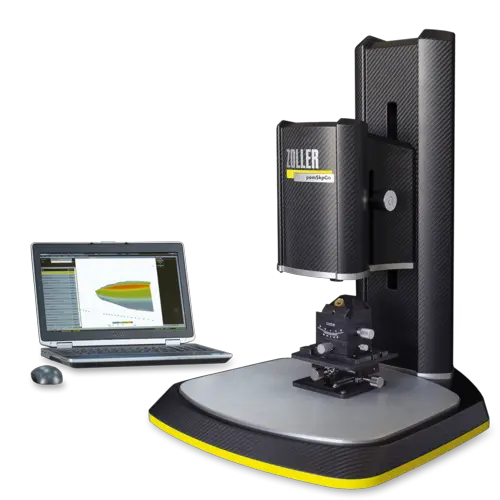

The ZOLLER pomSkpGo, brings laboratory-level tool inspection and measuring to the shopfloor.

This innovative machine is designed for inspecting the cutting-edge preparation of milling and drilling tools, as well as turntables. With unrestricted mobility, intuitive user guidance, and precise, traceable results, pomSkpGo is a game-changer in the field of tool inspection solutions. Its carbon construction allows for mobile use and ensures high accuracy, making it a key player in enhancing production efficiency and maintaining quality standards in manufacturing.

pomSkpGo combines leading ZOLLER measuring technology with the pomSoft software for quick commissioning, high measuring speed and quick alignment of tools

With its low weight and high stiffness due to carbon construction, pomSkpGo delivers laboratory-level results in a shopfloor environment

Automatic, lightning-quick measuring results including graphical 3D evaluation of the edge contour for precision tool inspection systems

Seamless documentation of extensive measurements ensures traceability and upholds quality standards in manufacturing

Easy-to-fit holders, quick and universal positioning of the cutting edge and intuitive operation make pomSkpGo a user-friendly tool management solution.

Seamless data transmission direct to your machine control unit, enhancing tool management solutions.

Book a free demo for the pomSkpGo at our Advanced Innovation Centre where you can see the full scope of ZOLLER technology and how it can transform the way you work.

Get the full technical data on the pomSkpGo today. Discover the key data points including information on measuring range, accuracy and a

full list of features.

Faraday House,

Woodyard Lane,

Foston,

Derby,

DE65 5BU

Faraday House, Woodyard Lane,

Foston, Derby, DE65 5BU

For any sales, product information or pricing inquiries fill out the form on the right and we’ll get back to you as soon as possible.