The internet of tools platform for greater security, transparency and flexibility.

zidCode 4.0

zidCode 4.0

Internet of Tools

IoT usually stands for Internet of Things. At ZOLLER, we like to think of it as the “Internet of Tools”. With the IoT platform zidCode 4.0 you can network your cutting tools with the processes in your production. Thanks to many output formats, zidCode 4.0 is compatible with many control systems.

With zidCode 4.0 you’ll understand all the prerequisites to make tool data, such as tool life, available at every level of a production process in order to digitally record the entire life cycle of a tool.

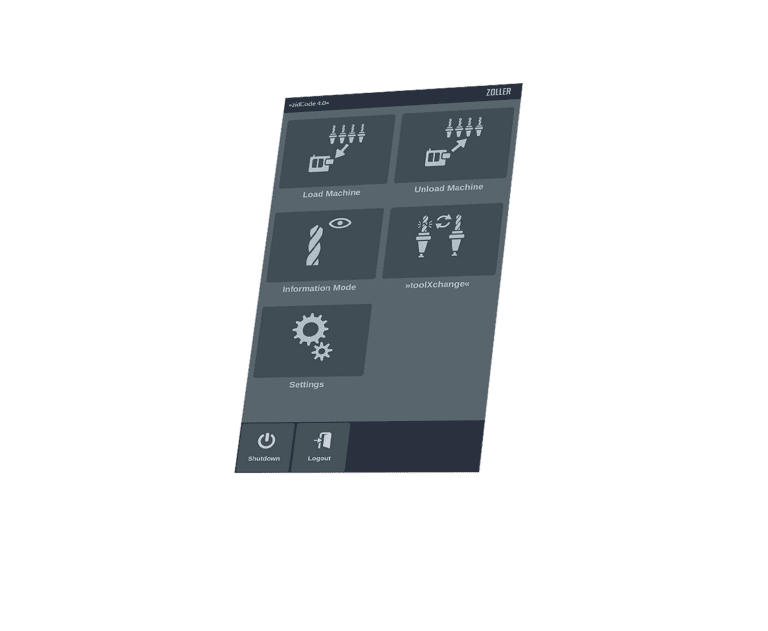

The large icons in the main menu of the touch panel take you quickly and directly to the desired function.

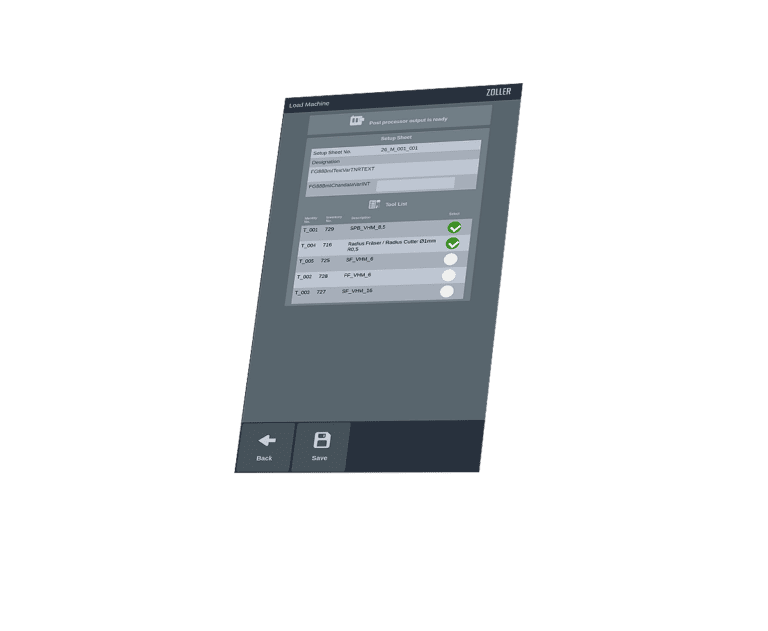

For scanning the tools on the CNC machine, zidCode 4.0 shows you a digital set-up sheet. Each scanned tool is visually labelle

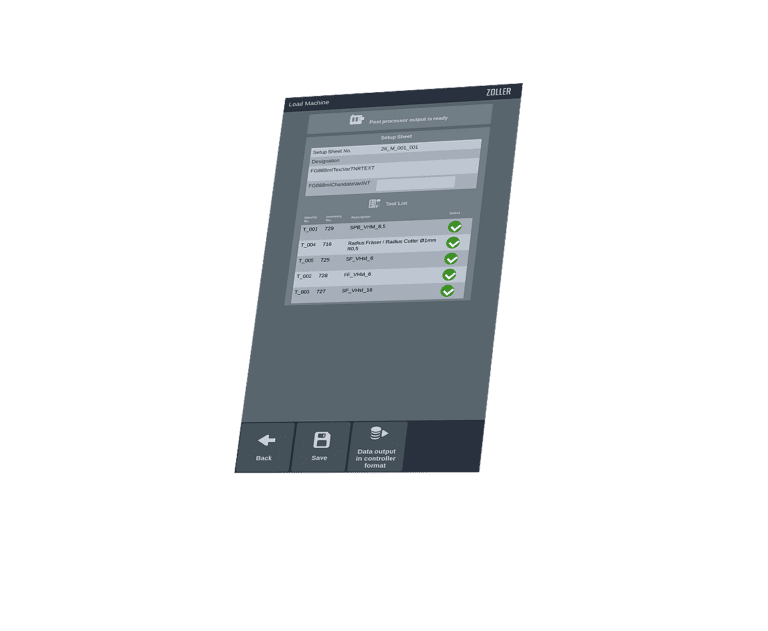

Once all the tools have been scanned, all you have to do is touch your specific button. The tool data is immediately prepared for the control system and transferred to the CNC machine without errors.

Simple to learn, easy to use

Functionality and usability go hand-in-hand when it comes to the zidCode 4.0. The intuitively designed user interface makes it simple and easy to transfer tool data to your CNC machine.

Complete tool performance

The zidCode 4.0 is the networked communication platform that records, manages and provides tool data in a closed process. As soon as data like tool life is recorded in your processes, it can flow directly into that tool’s data record.

1/6 Incoming Order

2/6 – CAD/CAM

3/6 – Storage

4/6 - Tool Presetting

5/6 – Production

6/6 – Delivery

Small investment for a huge return

With zidCode 4.0, you have all the elements for success at your fingertips. You gain security, accuracy and reliability, save time and make it easier for your employees to transfer data to the CNC machine. Even a lean, basic setup will quickly see these benefits.

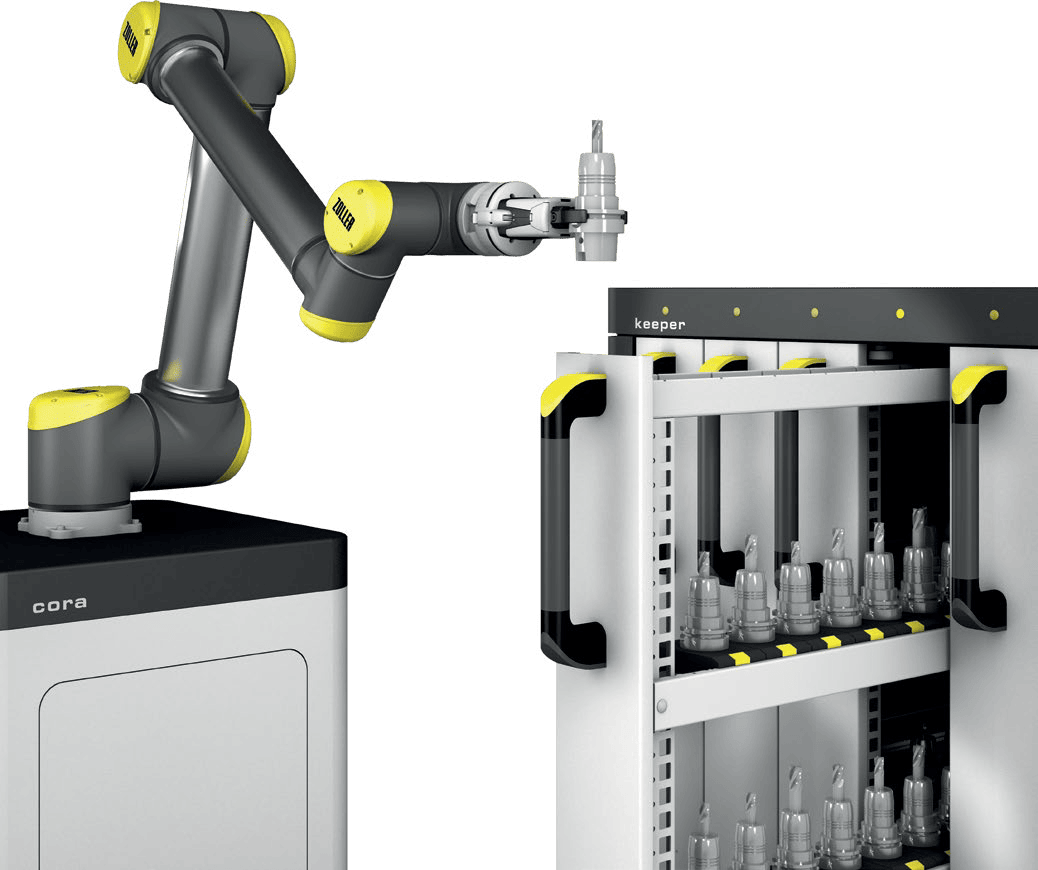

Ready for automation

Since the zidCode 4.0 prepares your production processes for dynamic management of tool data, you’ll have the foundation in place to incorporate even more automation!

The zidCode 4.0 is the ideal basis for quickly integrating ZOLLER automation solutions into your production process later on. With ZOLLER, you’ll always stay technologically up to date.

Technical Data

Features

The data transfer takes place via an exchange directory located in the network. For this purpose our software uses a post-processor to generate a required output format.

Requirements

- CNC machines with USB connection and a power access directly at the machine.

- ZOLLER presetting and measuring machine with image processing pilot 4.0 as of version 1.18.7

- Post-processor in pilot 4.0

- Marking of tool holders with 2D coding: either by laser marking, with the practical and enormously robust idLabel from ZOLLER or the ZOLLER idChip

Installation

- Barcode reader 1D/2D per CNC machine

- zidCode 4.0 unit, including zidCode 4.0 software package

- USB stick (documentation, manual, training videos)

- Cable kit (Ethernet, power cable)

- Software module zidCode 4.0 for installation on existing ZOLLER presetting and measuring machine

- Windows Services for installation on a server or PC: ZOLLER WebService and zidCodeService

Book your

in-person demo

Book a free demo for the zidCode 4.0 at our Advanced Innovation Centre where you can see the full scope of ZOLLER technology and how it can transform the way you work.

Download the full specifications

Get the full technical data on the zidCode 4.0 today. Discover the key data points including information on measuring range, accuracy and a full list of features.