The compact inspection solution for micro tools.

pomBasicMicro

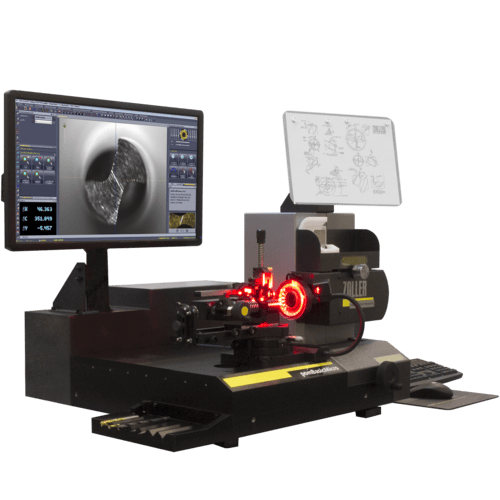

Dive into the world of micro tool inspection with the ZOLLER pomBasicMicro, a compact, process-oriented solution designed for the smallest tools.

pomBasicMicro

Overview

This innovative machine employs a unique video micro system monochromatic camera to capture data, enabling the assessment of angles, distances, wear and tear, quality of cutting edges, and grinding patterns. With individually adjustable image processing and intuitive operational capabilities, pomBasicMicro is a versatile tool that fits seamlessly into your metrology lab, goods-in area or manufacturing floor.

Compact and Precise

pomBasic’s space-saving design is suitable for any production environment, offering precise inspection and measuring solutions

Efficiency

Simply insert the tool, start the process, inspect and you’re done

User-Friendly

With a clear software interface for a simple inspection procedure and assistant-supported measuring procedures, pomBasic is an easy-to-use tool inspection and measuring solution

High Accuracy

Automatic optical edge detection, high-quality camera systems and automatic light controls ensure precision in tool inspection systems

Reliability and Integration

Direct data transmission to the grinding machine ensures seamless integration into your workflow, upholding quality standards in manufacturing

Scalability

With the software module regrind, pomBasic is capable of all wear and tear measurements, making it a comprehensive tool management solution

Book your

in-person demo

Book a free demo for the pomBasicMicro at our Advanced Innovation Centre where you can see the full scope of ZOLLER technology and how it can transform the way you work.

Download the full specifications

Get the full technical data on the pomBasicMicro today. Discover the key data points including information on measuring range, accuracy and a full list of features.