Tool presetting solutions for the automotive industry

ZOLLER

presetting

in automotive

The winning precision formula

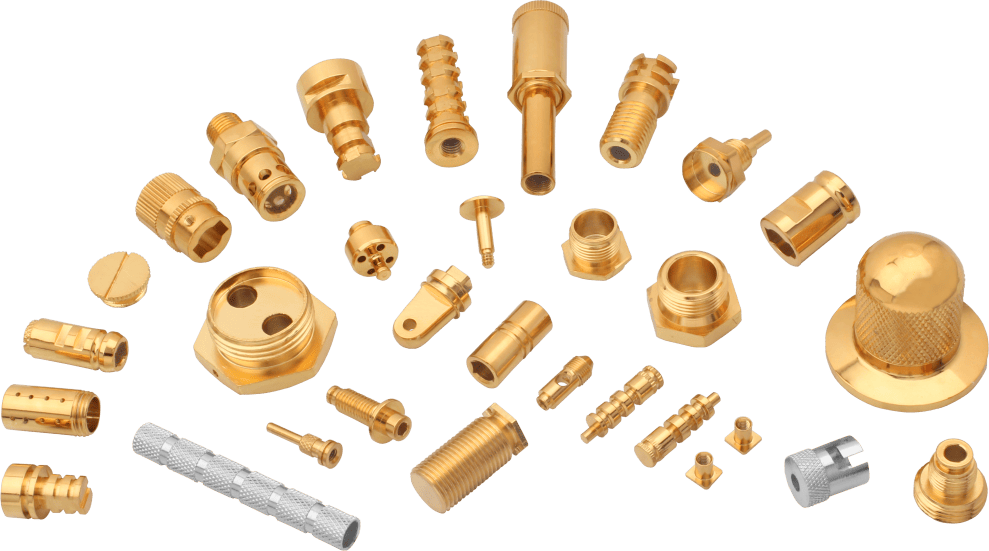

ZOLLER’s range of precision tool inspection systems allows for offline tool configurations with micron precision. Businesses rely on ZOLLER’s customised tool pre-setting, inspection, and management solutions to boost production efficiency and ensure consistent quality standards. The advanced tool inspection and measurement solutions ensure accuracy every step of the way and any tools that don’t meet the mark are automatically identified and removed, ensuring only the best tools make it to the production line.

Why use tool

presetting for the

automotive industry?

Maximised machine

capacity

Offline tool presetting solutions streamline the tool preparation process, eliminating downtime, maximising machine utilisation, and minimising tool set-up times. This enables CNC machines to focus on producing profitable products to boost productivity and drive growth.

Enhanced

accuracy

Achieve unparalleled accuracy through cutting-edge optical sensors and precise measurement technology to capture accurate and complex dimensions of tools. Ensure that the correct tool information is seamlessly integrated into CNC machining processes to guarantee consistently high-quality parts.

Reduced tooling

costs and scrap

Minimise scrap and reduce tooling costs by ensuring the accuracy and standardisation of tool measurement. Eliminate the need for costly rework and scrap by optimising tool selection to extend tool life, reduce breakages and minimise machine downtime.

Deliver results

ZOLLER’s sophisticated solutions are precise, swift, consistent and dependable. The non-contact, offline tool presetters deliver optimal results for manufacturers, accelerating throughput and providing a rapid return on investment. By guaranteeing the integrity of quality control processes for a diverse range of vehicle components and adhering to customers’ stringent quality specifications, ZOLLER systems provide the necessary precision for manufacturing critical automotive components.

Conquer your measurement challenges

ZOLLER tool management solutions are designed to withstand the challenges of everyday tool measuring. No matter the challenge your team faces, ZOLLER UK experts are on-hand to help you overcome challenging components.

Get in touch

Get in touch with an expert today. Discover the full power of optical measurement to save you time and money with your inspection routines.

Improve the consistency and accuracy of your measurements to create better products. Get in touch today to discover more.