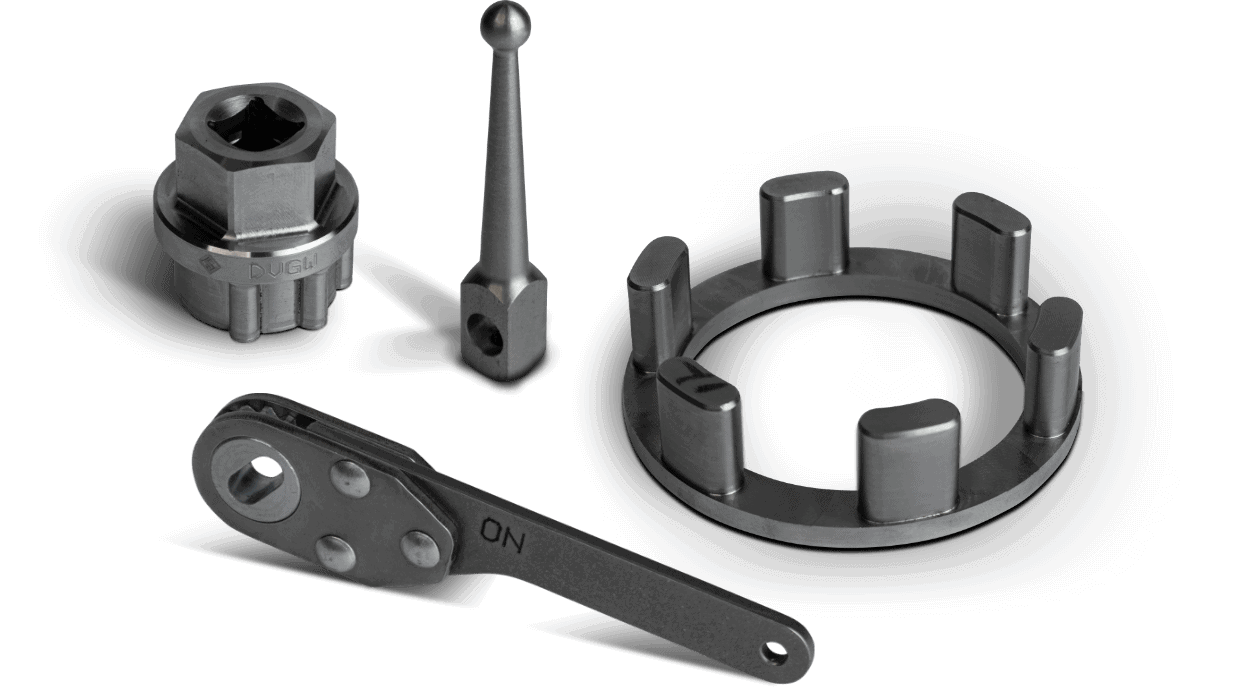

Tool presetting solutions for the manufacturing industry

ZOLLER presetting

in manufacturing

Reliable and accurate inspection

ZOLLER’s advanced presetting and measuring systems elevate machining processes, ensuring heightened tooling accuracy, fast tool changeovers, enhanced product performance and reduced downtime. ZOLLER excels in creating a more streamlined machining process, maximising spindle-on time, which instils confidence that every product produced is of the highest quality standard.

Why use tool

presetting for the

manufacturing industry?

Maximised machine capacity

Offline tool presetting solutions streamline the tool preparation process, eliminating downtime, maximising machine utilisation, and minimising tool set-up times. This enables CNC machines to focus on producing profitable products to boost productivity and drive growth.

Enhanced

accuracy

Achieve unparalleled accuracy through cutting-edge optical sensors and precise measurement technology to capture accurate and complex dimensions of tools. Ensure that the correct tool information is seamlessly integrated into CNC machining processes to guarantee consistently high-quality parts.

Reduced tooling

costs and scrap

Minimise scrap and reduce tooling costs by ensuring the accuracy and standardisation of tool measurement. Eliminate the need for costly rework and scrap by optimising tool selection to extend tool life, reduce breakages and minimise machine downtime.

Quality when it matters

Tool presetting and inspection is crucial in manufacturing for maintaining quality, efficiency, and reliability across various industries. ZOLLER tool presetters offer a comprehensive solution that caters to the diverse needs of manufacturers, ensuring accurate, repeatable measurements of tools, and contributing to the development of high-performance products. With the growing demand for fully automated processes and shopfloors, ZOLLER’s best-in-class solution is poised to play a significant role in the future of manufacturing.

Conquer your

measurement challenges

ZOLLER tool management solutions are designed to withstand the challenges of everyday tool measuring. No matter the challenge your team faces, ZOLLER UK experts are on-hand to help you overcome challenging components.

Get in touch

Get in touch with an expert today. Discover the full power of optical measurement to save you time and money with your inspection routines.

Improve the consistency and accuracy of your measurements to create better products. Get in touch today to discover more.