The all-inclusive software interface for tool measurement.

pilot 4.0

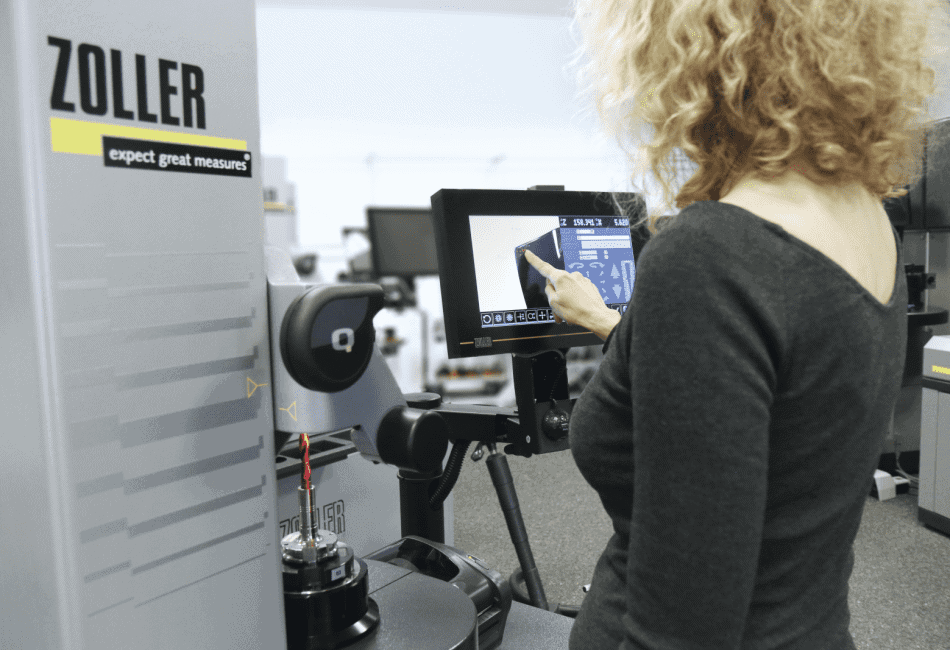

The ZOLLER pilot 4.0 software interface, is designed to simplify tool measurement. With an intuitive and easy-to-use interface, pilot 4.0 delivers reliable measurements and presets in record time. As the gateway to the entire ZOLLER range, pilot 4.0 provides access to all data and applications, making it a must-have for any modern production line.

pilot 4.0

Redefining Real-Time Tool Presetting

pilot 4.0 builds on the advanced control system of the pilot 1.0, pilot 2.0 and pilot 3.0 software before it – transforming your tool presetting process to create an effortlessly efficient production line.

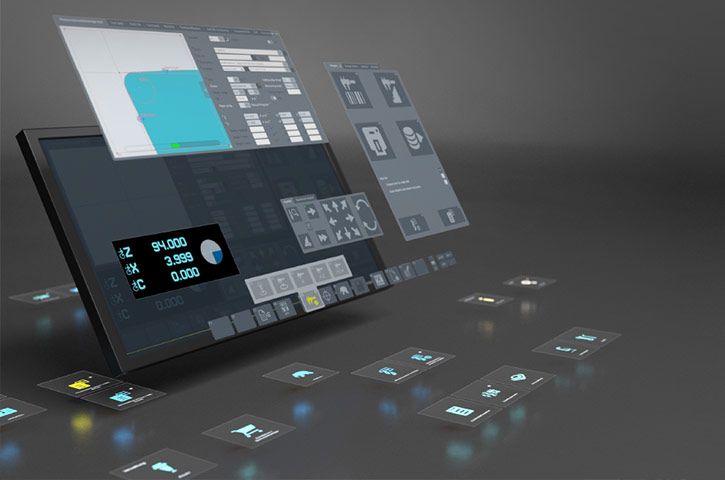

Simple – displays clear symbols for every function

Modern – offers state of the art work environment

Motivating – achieve success quicker than ever before

Efficient – always take the most direct path

pilot 4.0 Software Highlights

User-Friendly Interface

pilot 4.0 features a main menu designed for simplicity, making it easy to track and organise your buttons, collections, projects, and tools.

Customisable

Each operator can activate new buttons to fit within their role, creating a personalised work environment.

Advanced Detection

Advanced algorithms detect stages and edges, as well as quantities of either, simplifying the measuring process.

Anywhere Access

Whether at the workplace, at home, on the go, or on any ZOLLER machine, pilot 4.0 is available to you.

Efficiency and Profitability

With pilot 4.0, experience less machine downtime, a reduction in rejects, improved reliability, higher productivity, and increased profitability.

Features

- Touch and slide

- Intuitive touchscreen operating technology

- Fast and simple operation with no major training requirements

- Individual measuring procedures and user-specific menu navigation

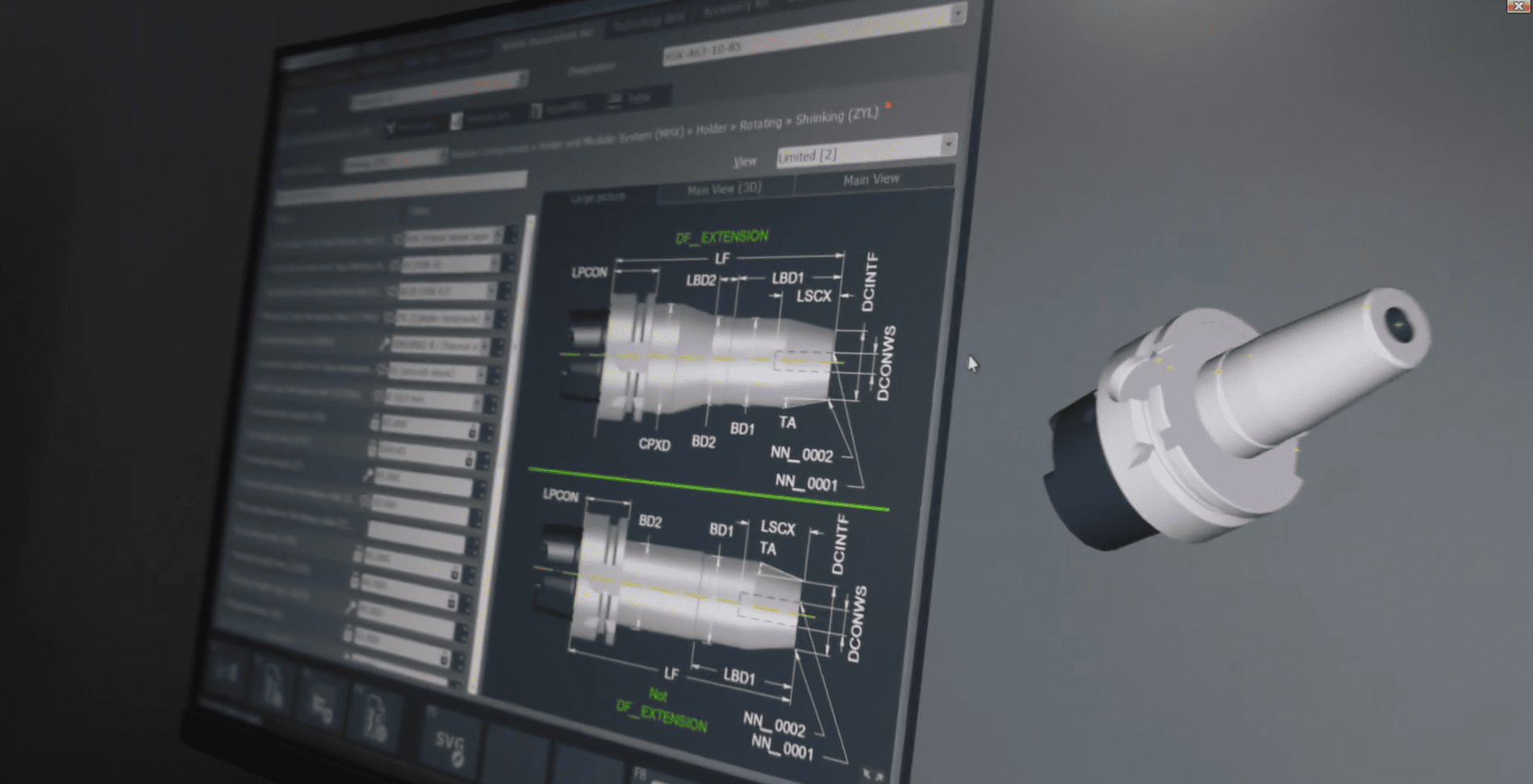

- Optimised presetting, measuring, inspection and management of all kinds of cutting tools

- Data communication via machine links and interfaces to external systems

Benefits

- Less machine downtime

- A reduction in rejects

- Improved reliability

- Higher productivity

- Increased profitability

- Selection from more than 200 automatic cutter shapes

- Measurement of setting sheets/tool lists at the push of a button with direct transfer to the tool machine

- Adjustable LED lighting for brilliant display and inspection of cutting edges

- Tool inspection, measurement and documentation in transmitted and incident light

- Management of tools, setting sheets/tool lists, individual components, graphs, warehouse and order system

Discover More About pilot 4.0

Harness the power of pilot 4.0 to import data from tool tables directly into the software, either by using a barcode scanner or manually entering the tool name.

pilot 4.0 enables you to execute all standard measurements effortlessly with a simple touch of a button. The software includes a diverse array of measurement templates suitable for most tool types and sizes. By recording measurement data, you can elevate the quality of your tools and boost your productivity.

pilot 4.0 Features:

What sets pilot 4.0 apart from other solutions on the market is its user-friendly interface that allows you to record measurement data in mere minutes. A simple swipe across the screen is all it takes.

Measurement

Template Library

At the core of the software is a library of measurement templates that cater to a wide range of tooling types. You can use these templates to scan tool dimensions directly from the table and swiftly measure the dimensions of cutting tools using your smartphone or tablet.

Custom Tool Templates

The software houses a vast number of predefined templates for different types of tools. Simply select the type of tool you wish to measure from the list of available templates, scan the corresponding barcode, and add it to your profile. You can also add your own custom measurement templates to the library for use with the app.

Easy Imports

Import tool data from multiple tools at once by scanning their barcodes with the app or entering the details manually. You can also create multiple profiles with different parameters for different groups of tools, ensuring accurate tool measurements and error prevention.

Multiple Measurements

The system allows for multiple measurements for each tool, meaning you can measure the length and width of each tool in a single session and also capture images of the tool for reference purposes.

Customisable Reports

The reports generated by pilot 4.0 can be customised to meet your specific business needs. You can select the fields to be included in the report and choose the formatting style. This personalisation allows you to track the data you need more accurately. Other features include the ability to export data as CSV and PDF files and synchronise data across multiple devices.

Hassle-Free Data Management

pilot 4.0 is capable of making intelligent observations to avoid unnecessary manual data entry, generating customised reports according to your specifications, recording the precise dimensions of your tools and equipment whenever you need them, and storing all relevant information about your tools and equipment in a centralised database for hassle-free data management.

Book your

in-person demo

Book a free demo of the pilot 4.0 software at our Advanced Innovation Centre where you can see the full scope of ZOLLER technology and how it can transform the way you work.

Download the full specifications

Want to gain more insight into our pilot 4.0 software? Download the brochure for a full list of features and discover how it will enable you to take ZOLLER machines even further.