The fully automated tactile measurement solution for crankshaft cutters with internal cutting edges.

aralon

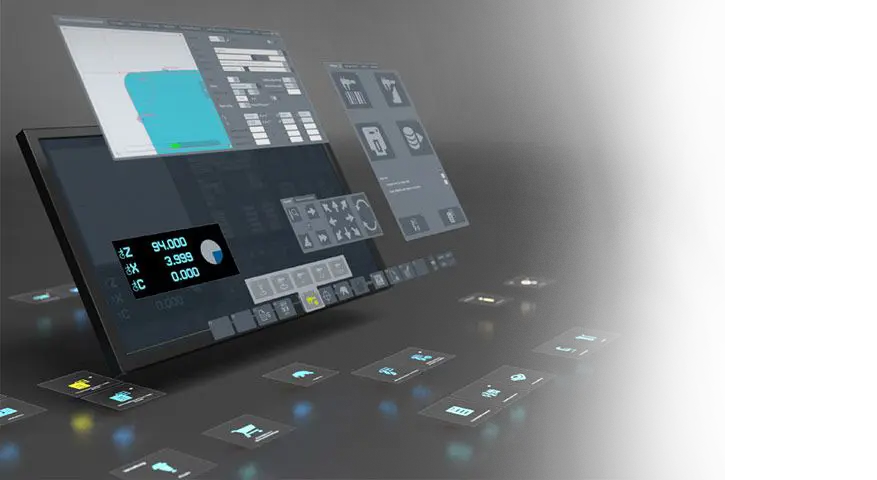

The aralon is Zoller’s innovative solution for the fully automated tactile measurement of crankshaft cutters with internal tool cutting edges. This precision tool presetting system is designed to enhance your production efficiency and uphold the highest quality standards in manufacturing.

aralon

Overview

A state-of-the-art presetting and measuring machine, it is equipped with a CNC-controlled electronic sensor that can be rotated automatically around 180°. This allows for individual positioning on all cutting edges, regardless of their alignment.

We offer specific attachment holders and holder rings for the exact positioning of the crankshaft milling cutter. Our intuitive software guides users swiftly and simply through the measuring task, making our tool management solutions user-friendly and efficient.

Precision at its Best

Four CNC-controlled axes and a variable 180° swivelling sensor ensure precise measurements

Clarity and Ease

Unambiguous information is provided through digital counters and an ‘analog’ dial gauge

Comprehensive Documentation

Seamless, customer-specific documentation if required

User-independent Operation

Intuitive software and fully automatic calibration of the measuring sensor at the attachment holder zero point

Quick Results

Achieve micron-accurate measuring results in seconds

Seamless Integration

Machine-conform, exact positioning of the crankshaft mill cutter using a specific attachment holder and holder ring

Book your

in-person demo

Book a free demo for the aralon at our Advanced Innovation Centre where you can see the full scope of ZOLLER technology and how it can transform the way you work.

Download the full specifications

Get the full technical data on the aralon today. Discover the key data points including information on measuring range, accuracy and a full list of features.