MACHINING GETS SMARTER WITH ZOLLER’S INDUSTRY 4.0. ZOLLER is taking steps to ensure your future machining processes evolve your factory into a Smart Factory

Through the introduction of automated systems and software to support your smooth transition into Industry 4.0.

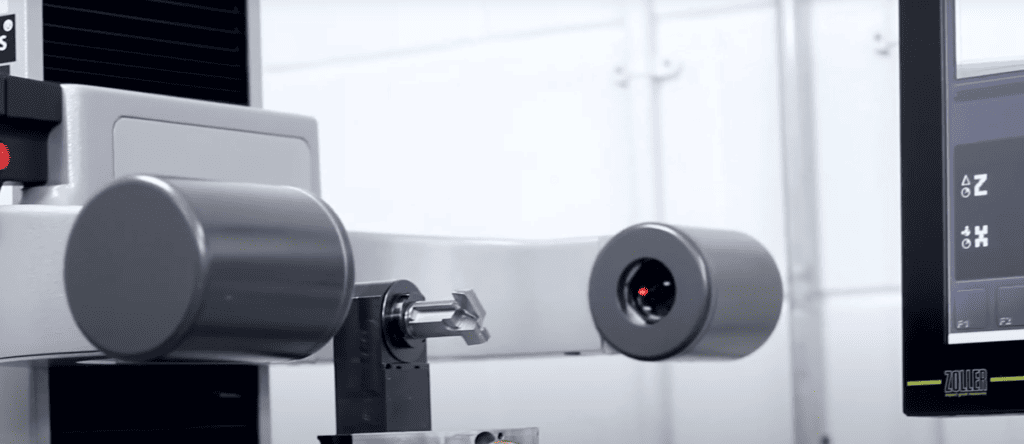

ZOLLER is world-renowned as the industry-leader of advanced precision presetting and measurement equipment. But what will ZOLLER contribute toward your business?

To put it simply presetting your tools increases production uptime, generating a knock-on effect on your machining processes. Having your tools readily set for CNC machining, before they are even required, reduces the time taken for tool setting and changes ensuring a swifter production routine.

Not only does tool presetting reduce production downtime, but it also increases accuracy in tooling through micron-precise measurement operations, assuring customers with a high level of confidence in complex component machining that is completely accurate at the first attempt.

But how can ZOLLER improve your machining processes of the future?

Industry 4.0 is widely regarded as the fourth industrial revolution, introducing advanced cyber-physical systems that support your physical processes and make decisions based on these. Creating what has been labelled a Smart Factory whereby systems can communicate and co-operate, carrying out automated data exchange in manufacturing technologies.

As the industry expert in tool presetting and measurement equipment, ZOLLER is ever-evolving and so are their solutions. ZOLLER has already taken steps to provide its current and prospective customers with the very latest and most advanced technology available worldwide, so much so that they are leading the way into the fourth industrial revolution with advanced cyber-physical developments to aid your tooling processes and help you to make a Smart Factory through implementation of smarter manufacturing processes. Here are some of the things ZOLLER is working on to improve your products.

1. Making Your Machining Processes More Intelligent

ZOLLER has developed much more advanced and secure tool data transfer methods to aid your progression as a Smart Factory. From presetter and storage system to the machine via a data matrix code on the tool holder, data is able to be transferred through scanning of this barcode. Accessing tool data such as tool life, storage location, presetting measurement instructions and the tool inventory number. Thus creating a seamless transition between worn and unworn tools saving you time.

2. Providing You with the Tools of Tomorrow

Working closely with a number of other companies as well as the Technical University of Darmstadt, ZOLLER is in the process of developing Smart Tools. These tools will eliminate search time through the ability to report their specific storage location, they will be able to store parameters and issue warning signals prior to exceeding limits avoiding subsequent crashes. These tools are being specifically designed to communicate directly with the machine.

3. digitaltwin

Also improving your machining processes is digital twin technology which generates a digital copy of the physical component allowing manufacturers to prepare production runs much more intelligently as well as create and manage tool data more efficiently. The >>digitaltwin<< software module aids your machining processes by allowing you to pre-plan how your production operation will perform. This newly developed technology benefits tool manufacturers as well as grinding and sharpening companies, allowing for customers to receive physical documented quality alongside its corresponding digital twin conforming to DIN 4000, as well as the added benefit of being able to create both 2D and 3D tool models using DIN 4000/ISO 13399 parameters.

4. z.One

The ZOLLER central database has specifically been created to organise all tool data throughout a tool’s lifecycle. From production planning to CAD/CAM, inventory, tool presetting/measurement, and finally to the machine, z.One works across the departmental boundaries. To save time, tool data can also be imported from other data storage systems.

Tomorrow’s Manufacturing Today

These new developments combine and allowing your machining processes to transcend into the future of manufacturing with ZOLLER. Industry 4.0 will introduce new levels of advancement in Zoller hardware and software, with one unwavering aim- Precision, Performance, Perfected- Zoller strive to improve your manufacturing processes so that your product performance is optimal.

ZOLLER allows for ease of expansion on a modular basis, presetting and measurement solutions are easily integrated into existing manufacturing operations and can be supplemented by further additional ZOLLER systems to increase capability, production volume and efficiency in the future. This fit-for-future approach enables room for growth dependent on future requirements, affording you investment security.

You can find out more about ZOLLER’s advanced technology at www.zoller-uk.com or visit the ZOLLER UK team on stand L2 at the Advanced Engineering 2016 event.