Why Offline Tool Measurement is Critical to Smart Factory Success

The fourth industrial revolution, Industry 4.0, has redefined how manufacturers think about efficiency, data and automation. In the smart factory, every process is connected, traceable and optimised for performance. While many companies focus on robotics, software and data analytics as part of this transition, offline tool measurement is an often-overlooked piece of the puzzle that can have […]

How Tool Presetting is Transforming UK Aerospace Manufacturing

The UK aerospace industry is under constant pressure to produce lighter, stronger and safer components with absolute precision. As tolerances tighten and production volumes increase, manufacturers need smart, reliable ways to boost productivity without compromising quality. One often overlooked solution making a big impact? Tool presetting. In this article, we explore how tool presetting technology […]

A guide to choosing the right tool presetter for your shopfloor

Selecting the right tool presetter is crucial for any machine shop looking to optimise efficiency and achieve high-precision results. From ensuring compatibility with current and future tooling, to evaluating service and support options, it is crucial to have the necessary knowledge to make an informed decision and unlock the full potential of a tool presetter […]

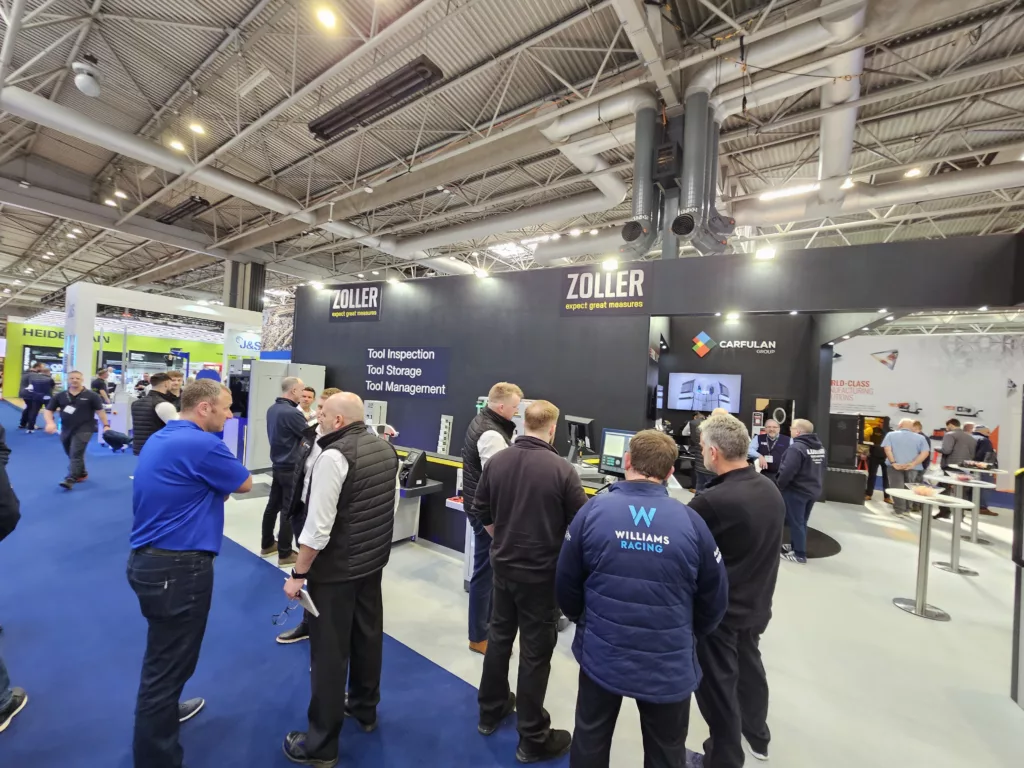

5 key highlights from ZOLLER UK at MACH 2024

MACH 2024 was the biggest and best year yet. The UK’s leading manufacturing exhibition saw over 26,000 visitors descend onto the NEC across five days to witness the most advanced manufacturing technologies available. ZOLLER UK had another incredibly successful year at MACH 2024, showcasing a range of its world-leading tool presetting and inspection technologies. The […]

Five reasons to visit ZOLLER UK at MACH 2024

The UK’s leading manufacturing exhibition, MACH 2024, is fast approaching and is set to be the biggest and best year yet, with more innovations under one roof than ever before. ZOLLER UK will be returning to MACH for the 10+ consecutive year, showcasing a range of world-leading tool presetting and inspection systems, including the launch […]

Equipping the Future of Manufacturing: ZOLLER & Industry 4.0

Industry 4.0, also referred to as the Fourth Industrial Revolution, represents the next transformative phase in the digitisation of the manufacturing sector. It is the convergence of information and operational technologies to enable seamless communication and collaboration between physical machines and digital systems. This combination, alongside advancements in data analytics, artificial intelligence, and machine learning, […]

Three key ways ZOLLER will reduce annual scrap rates

Minimal scrap is crucial in today’s competitive manufacturing environment. Wasted materials, lost production time and delays in delivery, means finding ways to reduce annual scrap rates is a key priority for modern manufacturers. ZOLLER offers a comprehensive solution designed to eliminate human error, ensure micron-level precision, and optimise the entire production process. ZOLLER’s automated tool […]

Eliminate operator error on the shopfloor with ZOLLER

Operator error is one of the largest challenges for modern manufacturers. Manual measurements, visual data interpretation and manual data entry all risk high levels of inconsistency and potential errors. This results in large amounts of scrap, machine crashes, out of tolerance tooling, costly reworks, ill-utilised production time, as well as large amounts of machine downtime. […]

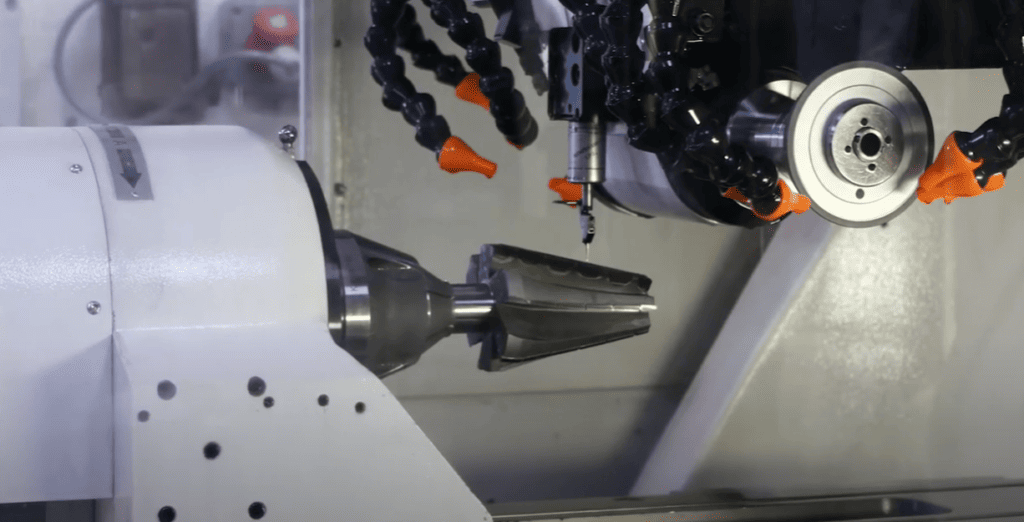

Maximise tooling performance with ZOLLER

In modern manufacturing, achieving consistent, high-quality products requires comprehensive quality control over every element of the production process, beginning with tooling. Maximising tooling performance requires unwavering precision and repeatability, ensuring every tool is accurate, and within the specified tolerances. ZOLLER UK delivers world-leading precision tool presetting, inspection, storage and management solutions, adding improved efficiency and […]

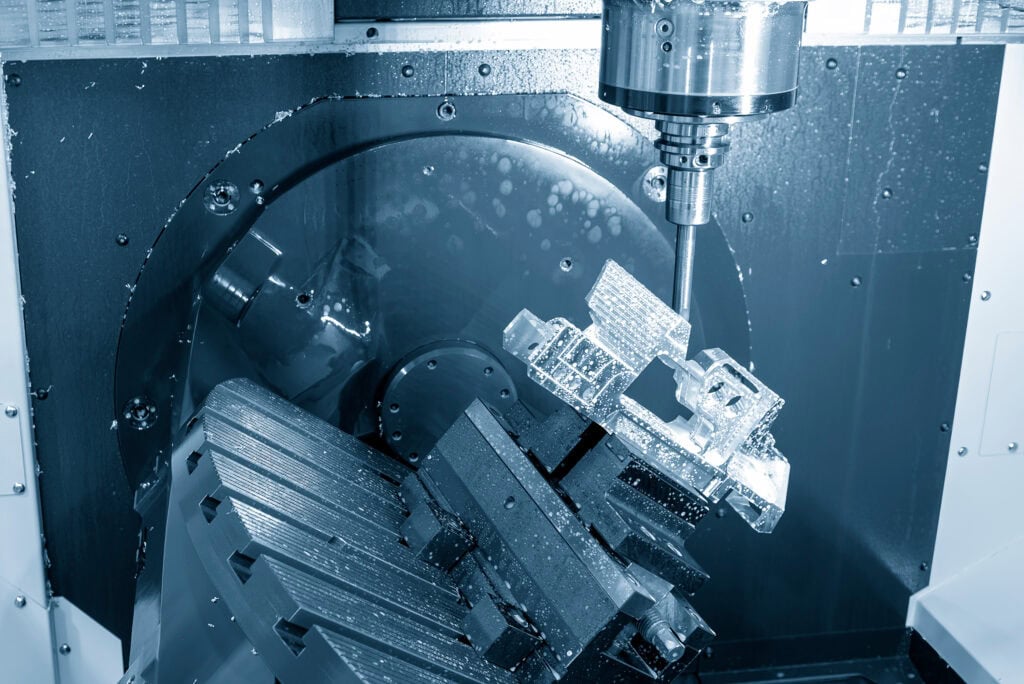

What are the 5 key challenges with setting tools directly onto a CNC machine?

As the manufacturing industry’s demands continue to grow, the technology and processes used by manufacturing companies must keep pace with modern advancements to remain competitive. However, traditional manual tool setting methods are now outdated and struggle to provide the accuracy and repeatability required by modern manufacturers. Setting tools directly onto a machine poses a number […]