Operator error is one of the largest challenges for modern manufacturers.

Manual measurements, visual data interpretation and manual data entry all risk high levels of inconsistency and potential errors. This results in large amounts of scrap, machine crashes, out of tolerance tooling, costly reworks, ill-utilised production time, as well as large amounts of machine downtime.

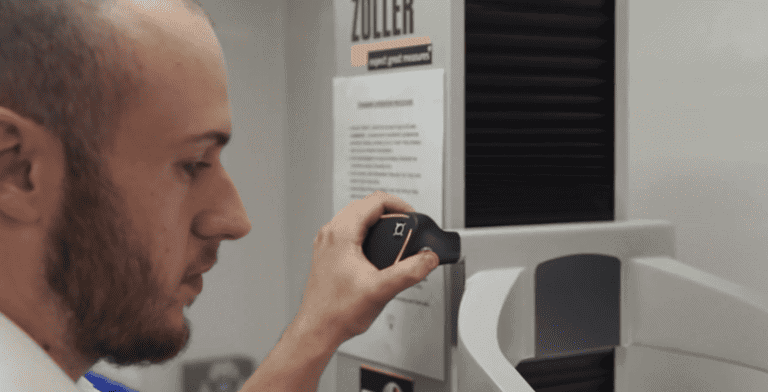

ZOLLER’s automated and digitalised tool presetting, measurement and inspection technologies eliminate operator error by eliminating the need for any operator reliance.

ZOLLER’s advanced technologies standardise all measurement and inspection processes, automatically communicating with CNC machines to prevent any operator error.

How ZOLLER eliminates operator error on the shopfloor

Automated & standardised tool measurement & inspection

ZOLLER standardises tool measurement by digitalising and automating the process to ensure that every measurement is completed identically. This eliminates any inconsistencies of manual tool measurement to guarantee accuracy and instil confidence in tooling being sent to the shopfloor.

Automatic & digitalised data transfers

ZOLLER automatically transfers and inputs tool measurement data onto the manufacturing machine to prevent any inaccurate tooling being loaded. This data can be transferred via a range of ZOLLER solutions, including: Data Output, zidcode, RFID chips and Data Matrix codes. Each tool has a unique identification code that stores its measurement data digitally to eliminate any risk of human error.

Enhanced process control

Instead of relying on operators to select and accurately measure the correct tooling, ZOLLER’s advanced tool management systems monitor tool tolerances and identify of any out of tolerance tooling before it enters into production to prevent any scrap or reworks being produced.

Tracking tool wear

Reliance on manual operator measurement means that tool wear often goes unnoticed by operators, leading to out of tolerance tooling entering production. ZOLLER’s tool management technology immediately identifies any out of tolerance tooling and notifies the operator to prevent it impacting production.