The modern manufacturing industry is becoming increasingly competitive, meaning manufacturers have to maximise all of their machines capacity. It is vital for modern manufacturers to have tools that can be preset quickly and accurately, without disrupting the production process.

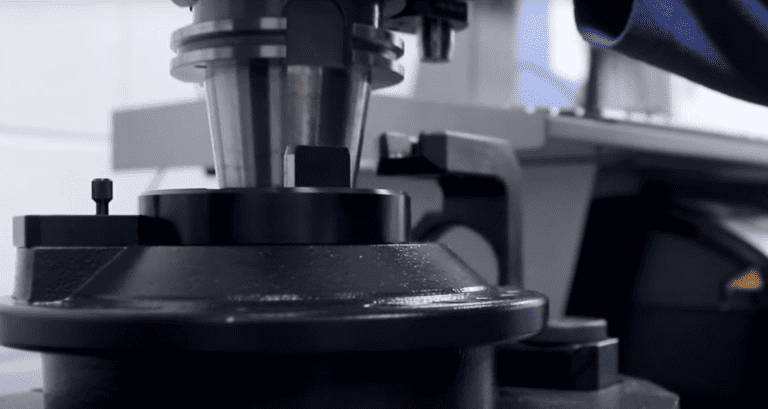

ZOLLER tool presetters offer a revolutionary solution to this challenge, by measuring tools offline away from CNC machines. ZOLLER tool presetters allow manufacturers to keep their machines running while they preset the next tool. This results in significant reductions in setup and changeover times, minimised machine downtime, and increased production and profitability.

Keep your machines tools running whilst presetting the next with ZOLLER UK

ZOLLER delivers world-leading precision tool presetting, inspection, storage and management solutions, that collect comprehensive tool data, including radii, angles, distances, lengths, and diameters, with micron-level precision. Using high-quality optics and cutting-edge programming, ZOLLER tool presetters gather data points in seconds compared to other systems. This data is gathered offline, away from CNC machines, meaning that while one tool is being used, another tool can be prepared ahead of time. This allows manufacturers to keep their machines tools running while minimising setup times, reducing machine downtime and increasing shopfloor productivity.

Reduced set up/ changeover time

ZOLLER tool presetters enable offline tool preseting, gathering all required data away from CNC machines before production even begins. This data is then electronically transferred directly to the CNC machine via barcode/RFID chips, so that the machine is ready to start production as soon as the tool is loaded. This dramatically reduces setup and changeover times by eliminating the need to measure tools on the machine, maximizing the efficiency of both CNC and tool presetting machines.

Minimised machine downtime

ZOLLER tool presetters also significantly minimises CNC machine downtime by ensuring accurate and consistent measurement data. ZOLLER tool presetters identify defects, wear, and inaccuracies in tools during the initial inspection, before the part is loaded into the machine. This prevents manual errors that could lead to tool failure and machine breakdowns. Manufacturers can be confident in the accuracy and reliability of their measurements, while other tools continue with other production jobs.

Increased production and profitability

ZOLLER unlocks existing CNC machining capacities by eliminating the need to measure and set tools on the machines. This allows machines to focus on producing profitable products, without unnecessarily spending production time on tool set-ups and changeovers. This provides manufacturers with hours of additional production time, significantly increasing their production capacity and profitability.