The UK aerospace industry is under constant pressure to produce lighter, stronger and safer components with absolute precision.

As tolerances tighten and production volumes increase, manufacturers need smart, reliable ways to boost productivity without compromising quality. One often overlooked solution making a big impact? Tool presetting.

In this article, we explore how tool presetting technology – particularly from ZOLLER UK – is helping aerospace manufacturers achieve faster set ups, better process control and more consistent part quality.

What is Tool Presetting?

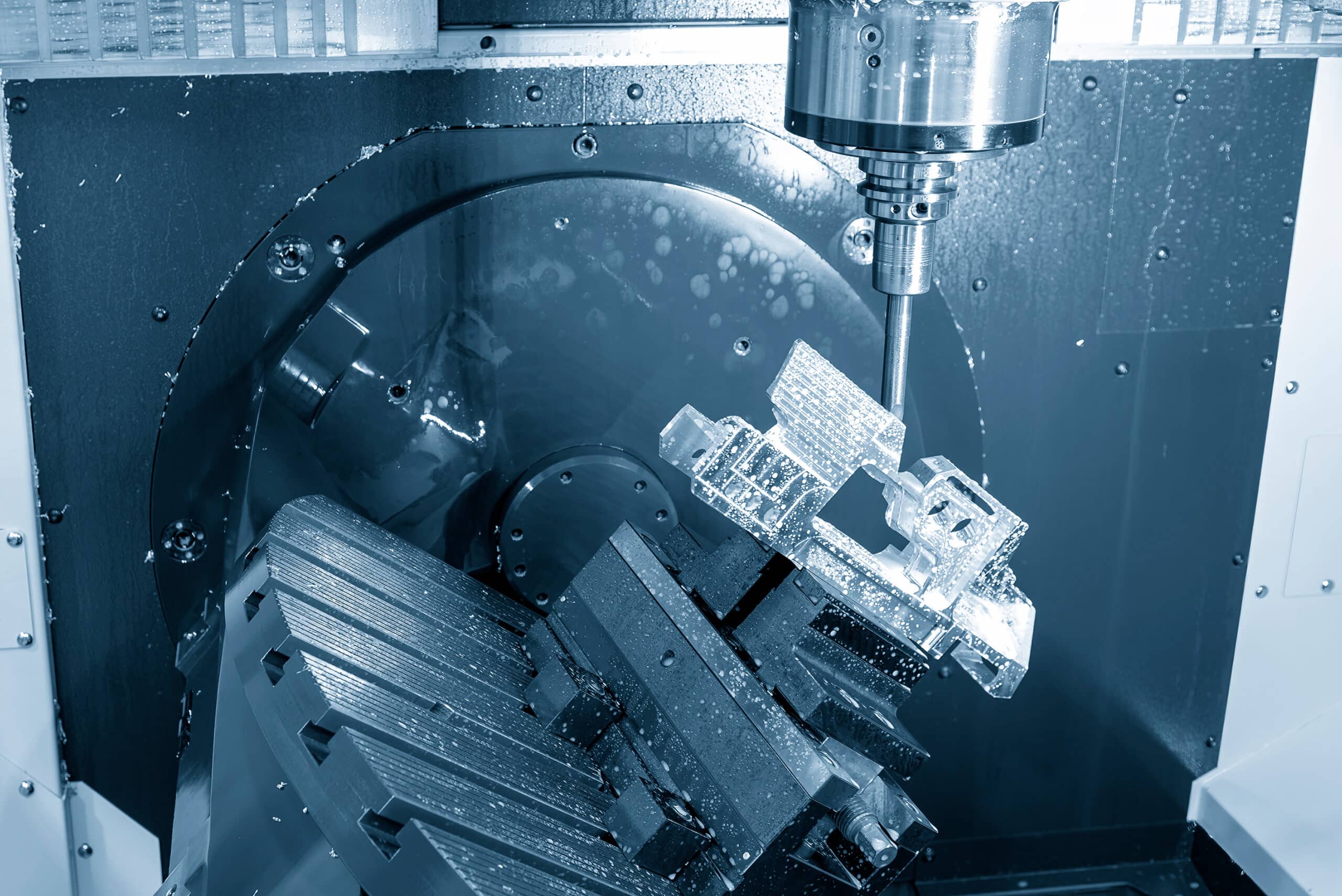

Tool presetting is the process of measuring and setting tools offline before they are loaded into a CNC machine. Using a dedicated tool presetter, manufacturers can accurately determine tool length, diameter, geometry and other parameters. These measurements are then transferred digitally to the CNC machine, reducing manual input and potential for error.

For aerospace manufacturing, where precision and repeatability are non-negotiable, the benefits of this approach are profound.

Why Aerospace Manufacturers Need Tool Presetting

1. Precision is Everything

Aircraft components demand extremely tight tolerances. Whether it’s a turbine blade or a structural bracket, even the smallest deviation can lead to performance issues. Tool presetting ensures that each tool is measured to exact specifications before use, significantly reducing the chance of machining errors.

2. Faster Set-up Times

Without presetting, operators must touch off tools manually inside the CNC machine, a process that can take minutes per tool. With presetting, tools arrive at the machine already measured and ready to go. For manufacturers running multiple tools per job, this can save hours of set-up time each week.

3. Increased Machine Uptime

Manual tool setting consumes valuable spindle time. By moving tool set up offline, CNC machines can stay in production longer, improving OEE (Overall Equipment Effectiveness). In aerospace machining, where machines are often booked for long, high-value runs, this added uptime directly boosts profitability.

4. Improved Tool Life & Monitoring

Modern tool presetters, like those from ZOLLER, not only measure tools but also inspect for wear, damage and alignment. This proactive approach to tool management extends tool life and helps avoid catastrophic tool failure, a major risk in high-speed aerospace machining.

ZOLLER UK: Supporting Aerospace Excellence

ZOLLER UK offers a range of tool presetting and inspection systems designed for the demanding needs of aerospace manufacturers. With advanced optics, intuitive touchscreen controls and seamless integration with CAM and tool management systems, ZOLLER machines deliver accuracy, speed and reliability.

Their smile, venturion, and pomBasic lines are already being used by leading aerospace suppliers across the UK to optimise set ups, reduce downtime and improve part consistency.

Digital Integration & Industry 4.0

Tool presetting isn’t just about measurement, it’s also a key enabler of digital manufacturing. ZOLLER systems can automatically send tool data to machines, databases and tool management platforms, ensuring traceability and consistency across the entire production process.

This integration supports the goals of Industry 4.0, helping aerospace manufacturers create smarter, more connected and more efficient production environments.

The Bottom Line

In an industry where performance, safety and quality are non-negotiable, aerospace manufacturers can’t afford inefficiencies. Tool presetting technology is no longer a luxury, it’s a competitive necessity.

With ZOLLER UK’s precision solutions, businesses can:

Reduce set-up times by up to 70%

Achieve consistent first-off part quality

Extend tool life and reduce scrap

Boost machine uptime and throughput

Ready to Take Off?

If you’re part of the UK aerospace manufacturing supply chain and looking to increase efficiency without compromising on precision, it’s time to explore tool presetting with ZOLLER UK.

Contact our team today to book a free demo or learn how our systems can transform your tool room and production performance.