Many companies assume that the only way to increase productivity and machine capacity on their shopfloor is to simply continue to increase the number of CNC machines on site. However, ZOLLER UK offers more cost-effective solutions which many companies are beginning to exploit and see the benefits of.

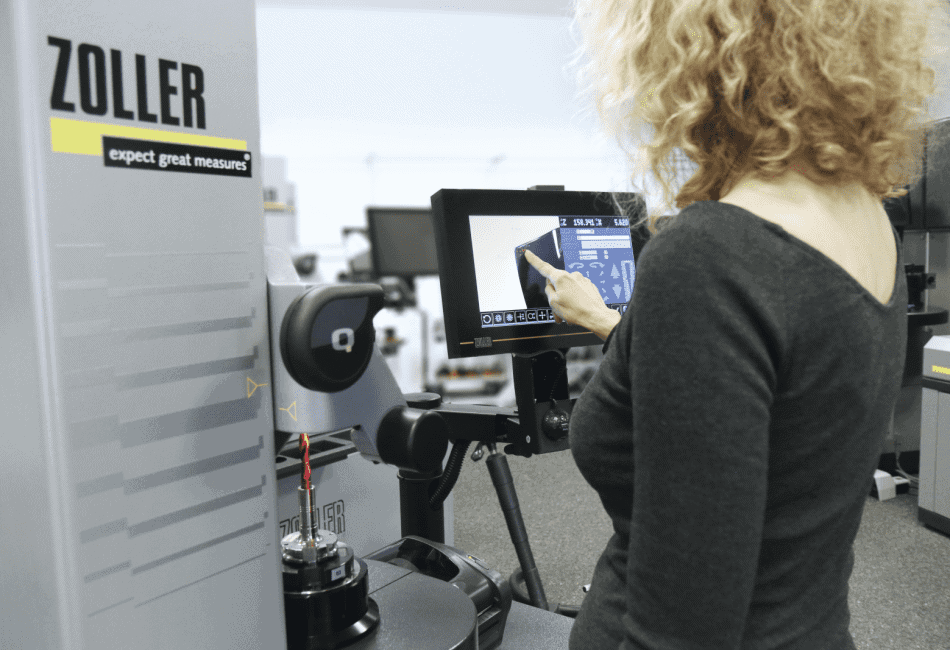

ZOLLER UK delivers world-leading precision tool presetting, inspection, storage and management solutions, adding improved efficiency and value to any manufacturing process. The range of tool management solutions available ensures that you can maximise productivity across you entire manufacturing process.

A ZOLLER tool presetter immediately increases productivity and machine capacity for a fraction of the price compared to buying a new CNC machine. Its ability to work simultaneously alongside manufacturing machines saves hundreds of hours, thousands of pounds and allows manufacturing machines to continue running at full capacity whilst increasing productivity across the shopfloor.

7 ways ZOLLER will increase productivity on your shopfloor

1. Offline tool pre-setting

ZOLLER’s offline tool presetters allow CNC machines to continue to run whilst tools are being checked, allowing greater production capacity and increased shopfloor productivity.

2. Less machine down-time

ZOLLER’s standardised and consistent tool measurements ensure accurate tools for each project, minimising the risk of tool damages, machine crashes or faulty components being produced. This results in less machine downtime, continuous production and maximum productivity.

3. Reduced scrap

The accuracy and precision of ZOLLER’s tool presetters is world renowned, providing total confidence that manufactured components will be produced right-first-time, minimising scrap and waste.

4. Full tool locatability

ZOLLER’s Tool Management Solutions (TMS) allow full locatability and traceability of tools across the shopfloor. Operators can track where tools are and who is using them at any point. This reduces time spent looking for tools and helps to immediately locate missing ones to prevent delays across the production process.

5. Adaptability

Presetting tools offline on ZOLLER tool presetters provides the flexibility to interchange between CNC machines in the event that one machine is down. This means that if one CNC machine fails, you can quickly load the tool and continue production on another machine to minimise disruptions and ensure continued productivity.

6. Reducing tool variety

ZOLLER’s software solutions provide a single view of tool utilisation, enabling operators to identify underutilised tools and streamline workflows, boosting productivity.

7. Tool usage planning

With ZOLLER’s tool management solutions, operators have total visibility as to which tools are available for which machine in advance of production. When programming data for a part, operators will be able to view parts that may not be available or need to be re-purchased.