Exactaform is a cutting tool specialist, supplying global industries such as aerospace, automotive and motorsport.

Exactaform invested in Genius tool measurement system, as well as a pomBasic tool inspection system from ZOLLER UK. This has allowed them to enhance the precision, quality and consistency of their products by ensuring the accuracy of their tooling.

ZOLLER UK delivers world-leading precision of tool-setting, inspection, storage and management solutions, adding improved efficiency and value to any manufacturing process.

Project Brief:

Exactaform manufacture a range of high precision cutting tools to leading industries. To ensure their high-quality standards, Exactaform sought to improve their quality and inspection capabilities.

Exactaform were looking to upgrade their tool measurement and inspection technology, and made contact with ZOLLER UK to explore their tool measurement solutions.

Key Account Manager for Exactaform, Martin Burns said:

“We had become very familiar with our existing tool measurement technology but we needed a tool measurement machine that provided better control of production to ensure right-first-time components every time.”

The Solution:

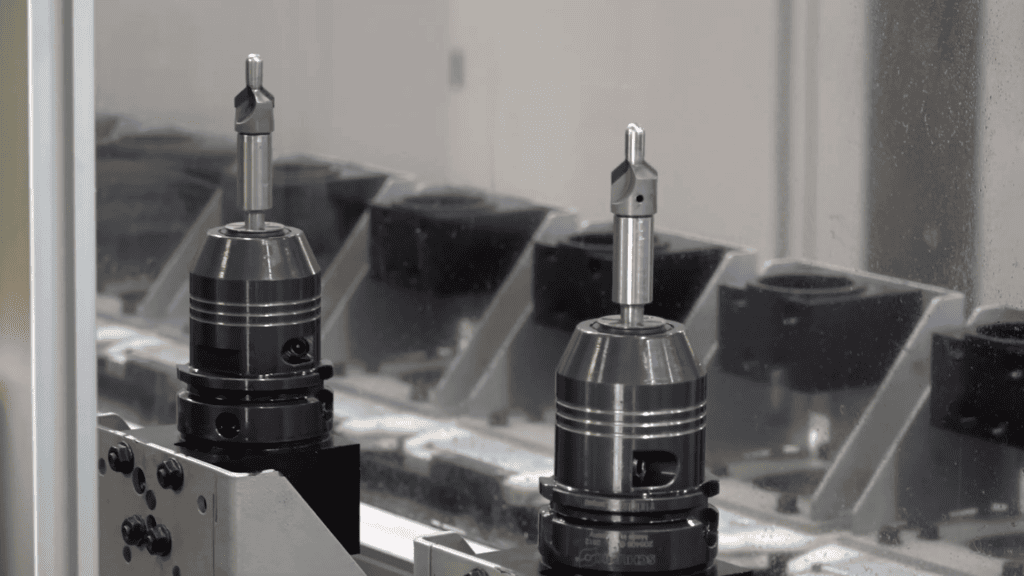

Exactaform invested in the Genius tool measurement system from ZOLLER UK to advance the precision, quality and consistency of their products by guaranteeing the accuracy of their tooling.

The Genius tool measurement machine is a versatile tool that can be used to inspect cutting tools quickly, easily, and accurately. It can test individual criteria or perform complete, fully automatic checks. The Genius saves time during planning, programming, and production by documenting measurement results in detail and transferring them to grinding machines at the click of a button.

Following their initial investment with ZOLLER UK, Exactaform invested in a pomBasic compact tool inspection system from ZOLLER UK to support their PCD finishing shop.

“We were drawn to the Genius because of its ease-of-use, accuracy and ability to measure Skp (the edge roundness of cutting tools). We invested in the pomBasic to undertake quick measurements of tools taken from our tool erosion machines, as well as supporting final inspection processes on the Genius,” said Martin.

The Benefits:

Investing in various tool measurement and inspection technologies from ZOLLER UK has allowed Exactaform to advance their product accuracy and upgrade their old machines to the latest technologies. Exactaform is now able to ensure full quality, accuracy and traceability of their components.

Martin explained the benefits of Exactaform’s latest investments with ZOLLER UK:

“There’s no doubting that the ZOLLER Genius has become the major element of our inspection processes. Compared with our previous tool measuring technology, the Genius is far easier to use. Since completing the ZOLLER UK training, our lead inspectors have now become very efficient on the Genius and it is now also frequently utilised by shopfloor operators, who use it for first-off, in-process and final inspection routines. This level of investment shows how seriously we take quality and maintains us as a major player in our sector. I’m sure ZOLLER UK will be a vital resource for many years to come.”

Why ZOLLER UK?

ZOLLER UK delivers world-leading precision of tool-setting, inspection, storage and management solutions, adding improved efficiency and value to any manufacturing process.

ZOLLER UK is part of the Carfulan Group who specialise in providing the most advanced manufacturing technologies available, helping customers across their five divisions to achieve optimal performance and end-product excellence.