Optimised shopfloor production efficiency is vital for modern manufacturers in an increasingly competitive market. Manufacturers need to ensure fast production, short turn-arounds and competitive pricing without sacrificing on product quality. When a manufacturing shopfloor is working at full capacity, the immediate thought is to buy another manufacturing machine to increase capacity… but what if there was a way to increase capacity without buying another machine and instead optimising the existing machines production capacity for a fraction of the price?

ZOLLER UK delivers world-leading precision tool setting, inspection, storage and management solutions, adding improved efficiency and value to any manufacturing and production processes. ZOLLER’s tool management solutions optimise productivity across the shopfloor, maximising machine capacity whilst ensuring accuracy and consistency of every product.

How ZOLLER UK can help optimise shopfloor efficiency

Unlock machine capacity

ZOLLER UK unlocks machine capacity by enabling the continuous production of other components whilst tools are being preset in advance of the next job.

Support seamless integration

ZOLLER’s tool management solutions seamlessly integrate and enhance existing production processes across the shopfloor; ensuring speed, accuracy and consistency.

Right-first-time products

ZOLLER’s offline tool presetters guarantee ‘right first-time’ cutting, reducing the risk of damaged tools, tool life and materials.

Improved process control

Each tool can be tracked and monitored for any potential defaults to ensure only accurate and high-quality tools can enter into machines for production.

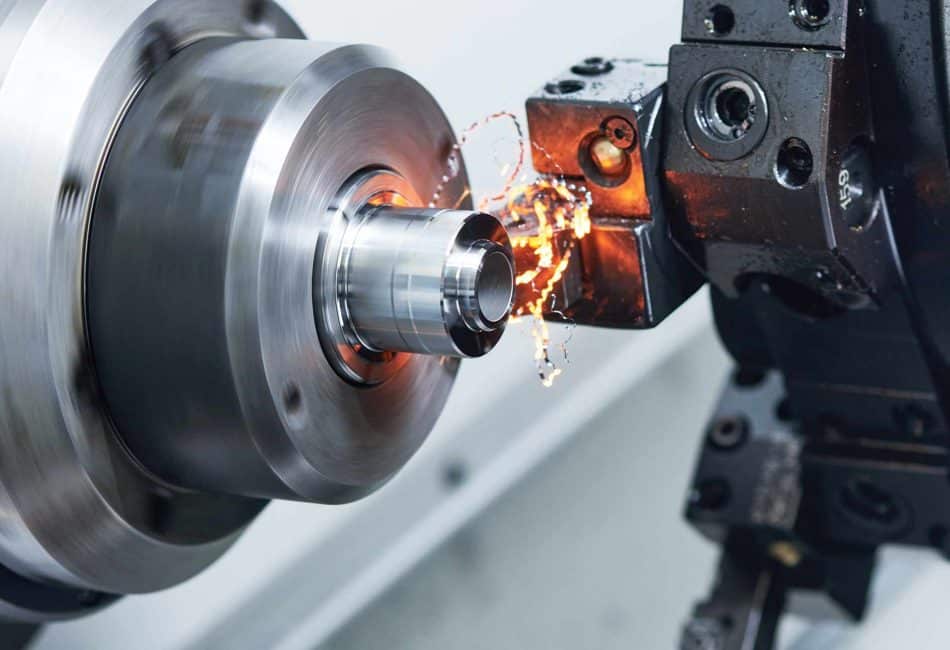

Optimised cutting tool performance

ZOLLER UK tool presetting solutions optimise cutting tool performance by ensuring the accuracy and quality of tooling before production, boosting shopfloor productivity.

Increased Flexibility

A single tool presetter serves multiple machines, allowing them to continue running and if a machine breaks down, tools can be quickly loaded onto another machine.