Tool presetting is essential for modern manufacturers to maximize CNC machine capacity and produce high-quality products efficiently.

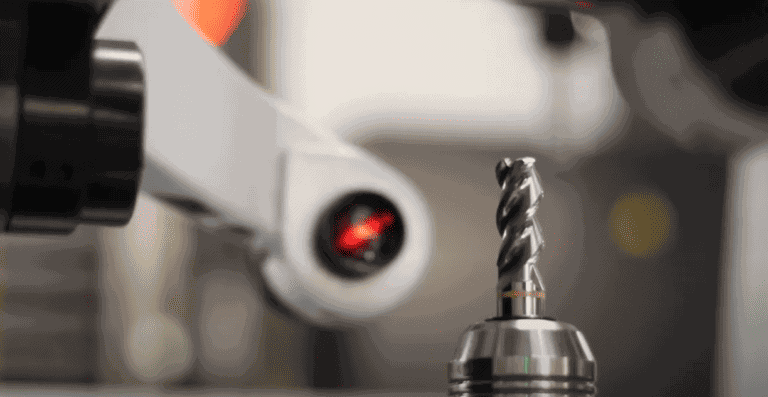

ZOLLER UK provides world-leading precision tool presetting, inspection, storage and management solutions, adding improved efficiency and value to any manufacturing process. ZOLLER’s digitalised and automatic offline tool presetters ensure accurate and consistent measurements of a manufacturers tool to monitor quality and conditions of tools throughout their lifecycle.

ZOLLER’s offline tool presetters provide a simple and effective solution to measure and inspect tools away from CNC machines, freeing up machine time and increasing productivity.

Why it is vital for modern manufacturers to preset tools

Productivity

ZOLLER solutionssignificantly speed up production times by reducing machine downtime and increasing CNC machine utilisation. ZOLLER tool presetters can preset tools in seconds, transferring the data directly to the CNC machine using RFID chips, ZidCode, or barcodes. This can offer significant time savings per shift, leading to hundreds of hours saved and converted into production time.

Accuracy

High accuracy is essential in modern-day manufacturing. ZOLLER’s tool presetters measure down to a single micron and provide comprehensive data on a tool life expectancy and condition eliminating the risk of human error. ZOLLER’s high-quality optics facilitate close inspection of cutting edges, radii, angles, and other tool data, enabling high-level accuracy automatic software solutions.

Efficiency

ZOLLER tool presetters are vital to improve efficiency in manufacturing because they eliminate machine downtime and input errors. By measuring tools offline, ZOLLER tool presetters allow CNC machines to operate uninterrupted. This reduces machine downtime, input errors, scrap, and rework, resulting in significant rise in efficiency.

Reliability & Repeatability

ZOLLER’s solutions help manufacturers achieve reliable, repeatable, and error-free production. ZOLLER’s world-renowned tool presetters provide consistent measurements in any shopfloor setting, giving manufacturers confidence that their CNC machines will operate smoothly and produce right-first-time components, whilst ZOLLER TMS software tracks tool location and condition, identifying potential issues early to prevent production disruptions.